Type:

Specification:

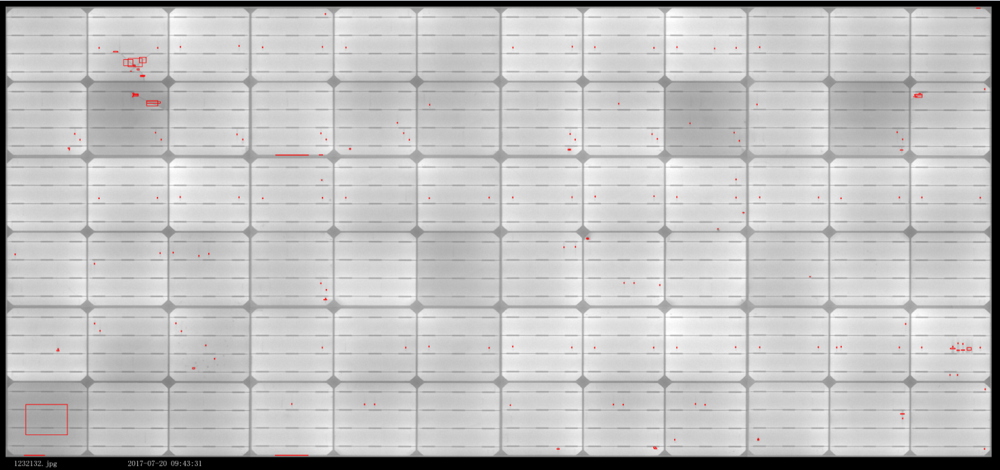

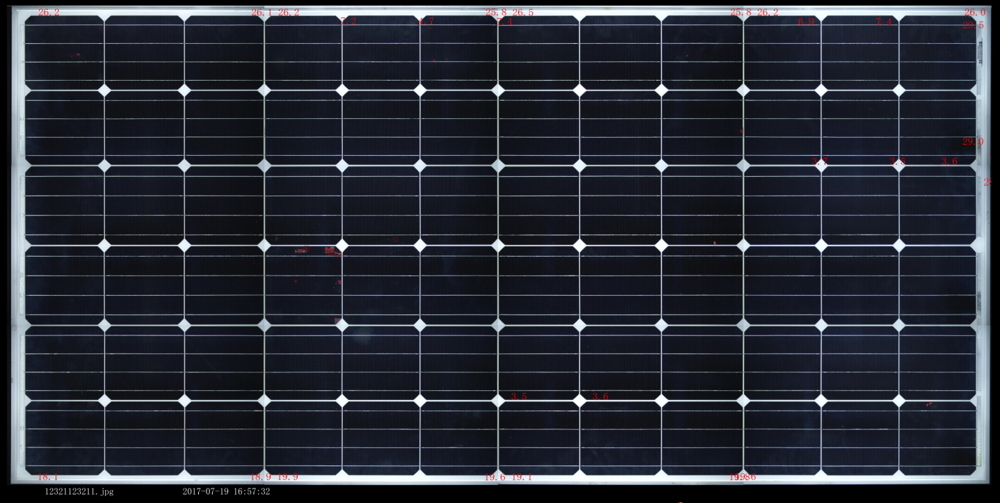

Used in testing the solar module Crack,breakage, Black Spot,Mixed Wafers,Process Defect,Cold Solder Joint phenomenon

|

Equipment performance |

Description |

Remarks |

|

Testing cycle (s) |

≤24s |

|

|

Testing range (mm) |

Conventional modules, double-glazed modules, film-mounted modules and halved modules. 156 polycrystalline/monocrystalline 72-cell module: 1,956 * 992 * 40 mm (46 mm) 60-cell module: 1,650 * 992 * 40 mm (35 mm) |

Universal for before and after the layer |

|

Feeding method |

Feeding by the long edge, conveying by the belt, adjustable conveying spacing. |

|

|

Testing method |

Upward perpendicular projection of four cameras and imaging by three movements of the modules. |

|

|

Human-machine interface |

Testing mode: For normal testing on the production line, as well as for monitoring and volume production statistics. Assembly line mode: For transmission on the assembly line, without EL testing. Commissioning mode: Individual control for each module of the equipment for commissioning and maintenance |

|

|

Software |

EL tester 1) Automatic module barcode recognition 2) Monocrystalline auxiliary diagnosis 3) MES interfacing 4) Query 5) Other functions |

|

|

Image storage |

Save the EL pictures in the name of the module barcode and upload to MES system |

|

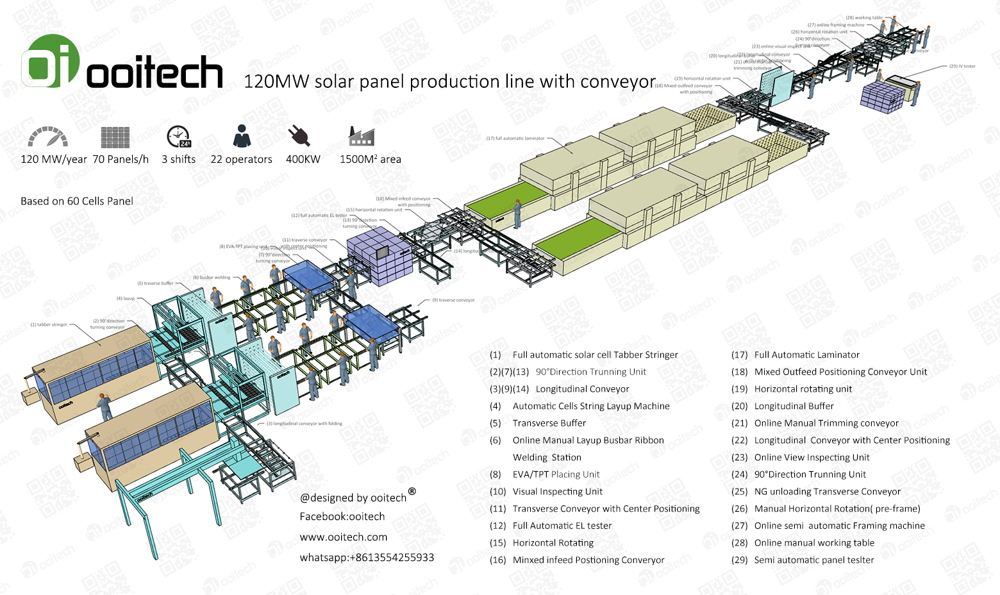

Ooitech, One-stop Solution For Solar Module Making Machines.

Has The Following Required Machinery And Accessories

Ooitech “Turnkey Solution” Includes: Factory Construction, Facility Layout, Raw Materials BOM guidance, Production Procedure assitance, Solar Power Station installation technical support Etc.

Supply 10MW-500MW Solar Module Making Machines

Update the traditional PV line to newest MBB solar panel production line.

Solar Cell Tabber Stringer Machine

Automatic Solder Bussing Machine

2345 Double Chamber Fully Automatic Solar Panel Laminating Machine of Solar Panel Production Line

2345 Double Chamber Fully Automatic Solar Panel Laminating Machine of Solar Panel Production Line  Tabber Stringer Machine - MBB Full Automatic Solar Cell Stringer Machine 3600PCS/H

Tabber Stringer Machine - MBB Full Automatic Solar Cell Stringer Machine 3600PCS/H 156-210 Mbb 50-60s/Panel Auto Solar Cell String Bussing Machine

156-210 Mbb 50-60s/Panel Auto Solar Cell String Bussing Machine Solar Module Gluing and Framing Machine - Solar Manufacturing Machine

Solar Module Gluing and Framing Machine - Solar Manufacturing Machine Sun Simulator Solar Panel Tester - Solar Panel Making Machine

Sun Simulator Solar Panel Tester - Solar Panel Making Machine 2023 New 9BB 16BB 20BB MBB PERC TOPCon HJT Solar Cell Tabber and Stringer

2023 New 9BB 16BB 20BB MBB PERC TOPCon HJT Solar Cell Tabber and StringerBuilding 1, Zixin Industrial Park, Yangguang Ave,Jiangxia Economic Development Zone, Wuhan of China

Mon-Fri: 8.30AM-5.30PM (UTC+8)