Type:

Specification:

2022 Solar Cell Laser Scribing Machine With Auto Devide

Machine Function

Suitable for scribing or cutting the Solar Cells and Silicon Wafers in solar PV industry, including the mono-si and poly-si solar cells and silicon wafer.

It can realize functions such as automatic material feeding, cell positioning, laser scribing, and boxing. Professional control software, free maintenance, easy operation.

Machine Features

l Advanced scribing technology:

Adopt fiber laser source, good quality laser beam, slim laser scribing line, more uniform solar cell cutting surface, small damage to solar cell, high accuracy cutting.

l High efficiency:

High laser scribing speed, producing capacity can reach to 1500 full cells/hour

l Accuracy positioning:

Solar cell full automatic positioning, positioning accuracy ≤±0.1mm

l High automation level:

Solar cell automatic loading and unloading, automatic positioning, automatic scribing. Stable performance, low failure rate, easy maintenance.

Technical Parameters

|

Items |

Parameters and configuration |

|

Positioning accuracy |

Cell automatic positioning, error range ≤±0.1 mm |

|

Laser wavelength (nm) |

1064 |

|

Maximum scribing speed |

500 mm/s Adjustable |

|

Actual output |

1800 full cells/hour (calculated by single cut of 166mm size cell) |

|

Accuracy of scribing |

±0.1mm |

|

Line width |

40μm |

|

Work table area/trip |

Maximum working area: 245×245 mm (2pcs) Module max running area :300×300 mm |

|

Material size |

156 x156~210 x210mm monocrystalline silicon, polycrystalline silicon solar cells and silicon wafers |

|

Material thickness |

0.18-0.30 mm |

|

Cell thickness deviation |

±10μm |

|

Breakage rate |

≤0.1% |

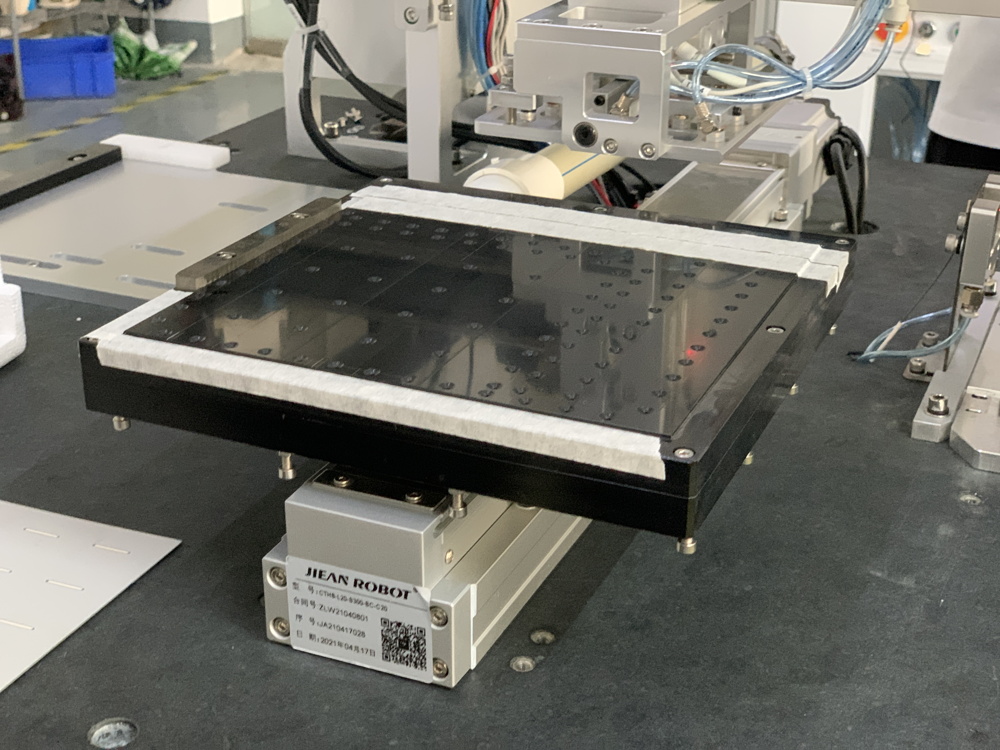

Detail picture

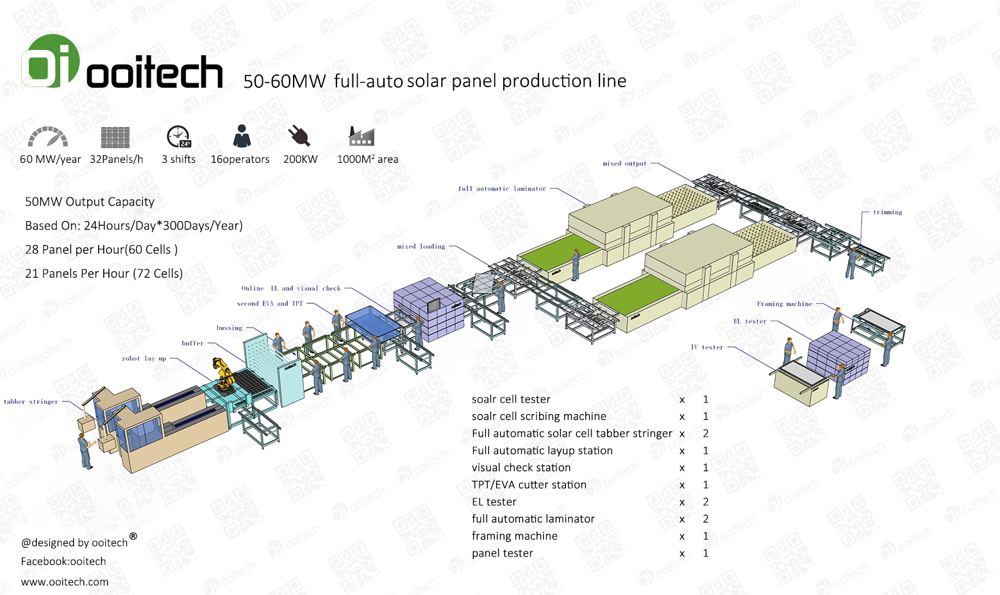

Ooitech, One-stop Solution For Solar Module Manufacturing Equipment.

Has The Following Required Machinery And Accessories

Ooitech “Turnkey Solution” Includes: Factory Construction, Facility Layout, Raw Materials BOM guidance, Production Procedure assitance, Solar Power Station installation technical support Etc.

Supply 10MW-250MW Solar Module Manufacturing Equipment

Update the traditional PV line to newest MBB solar panel production line.

Solar Cell Tabber Stringer Machine

Automatic Solder Bussing Machine

Solar Cell Non-Destructive Laser Scribing Machine 3600 PCS/H 6000PCS/H

Solar Cell Non-Destructive Laser Scribing Machine 3600 PCS/H 6000PCS/H Tabber and Stringer Machine - MBB Solar Cell Stringer

Tabber and Stringer Machine - MBB Solar Cell Stringer Solar Stringer Layup Machine - Solar Panel Production Line

Solar Stringer Layup Machine - Solar Panel Production Line 156-210 Mbb 50-60s/Panel Auto Solar Cell String Bussing Machine

156-210 Mbb 50-60s/Panel Auto Solar Cell String Bussing Machine Tabber Stringer Machine - MBB Full Automatic Solar Cell Stringer Machine 3600PCS/H

Tabber Stringer Machine - MBB Full Automatic Solar Cell Stringer Machine 3600PCS/H 2345 Double Chamber Fully Automatic Solar Panel Laminating Machine of Solar Panel Production Line

2345 Double Chamber Fully Automatic Solar Panel Laminating Machine of Solar Panel Production Line Building 1, Zixin Industrial Park, Yangguang Ave,Jiangxia Economic Development Zone, Wuhan of China

Mon-Fri: 8.30AM-5.30PM (UTC+8)