Type:

Specification:

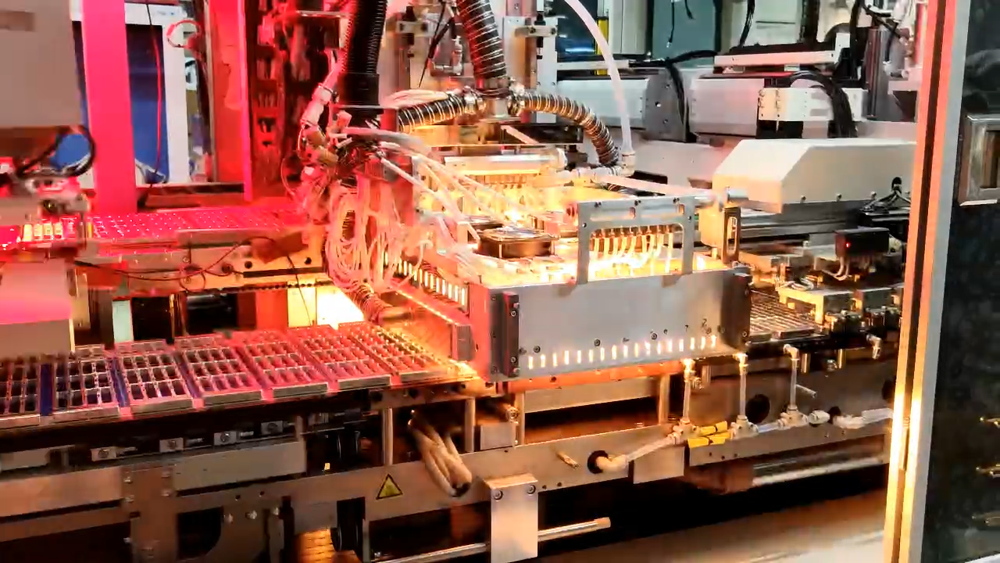

Tabber and stringer machine is to weld the solar cells one by one through copper ribbon, and the cells are connected in series to form a string. The entire welding process is fully automated.

|

Model |

OCH-MS40K |

OCH-MS100B |

|

Soldering capacity |

3400-3600 Cells/hour |

6000 cells/hour |

|

Soldering Method |

IR soldering |

|

|

Cell Size |

156~230mm Half Cut |

156~220mm crystalline cell and its half-cut or 1/3 cut Cells |

|

Busbar |

3BB-12BB (tooling replacement is required for different busbar cells) |

3BB-15BB |

|

Cell Thickness |

170um~200um |

|

|

Max String Length |

2200mm |

2450mm |

|

Cell Spacing |

1.8- 6mm Adjustable |

|

|

Bad Soldered String |

Traditional cells:≤2%;MBB cells:≤2.5% |

Traditional cells:<2%;MBB cells:<3% |

|

Power Supply |

Three-phase 380V, 50Hz Three-phase five-wire (L1/L2/L3/N/PE) |

|

|

wire specification |

4x16mm2+1x10mm2 |

|

|

Power |

Average power: 20 kW Peak power: 40 kW |

|

|

Air Supply |

Pressure: 0.6-0.8Mpa |

|

|

Air consumption |

Peak 1500L/min average 1000L/Min |

>2000L/min |

|

Standard Configuration |

9BB 1/2 Cell Kit |

Only Include 10BB Kit with machine, anyh additional kit will come with additional cost. Machine is capable to run 5BB-15BB upon purchase of respective tooling kits. |

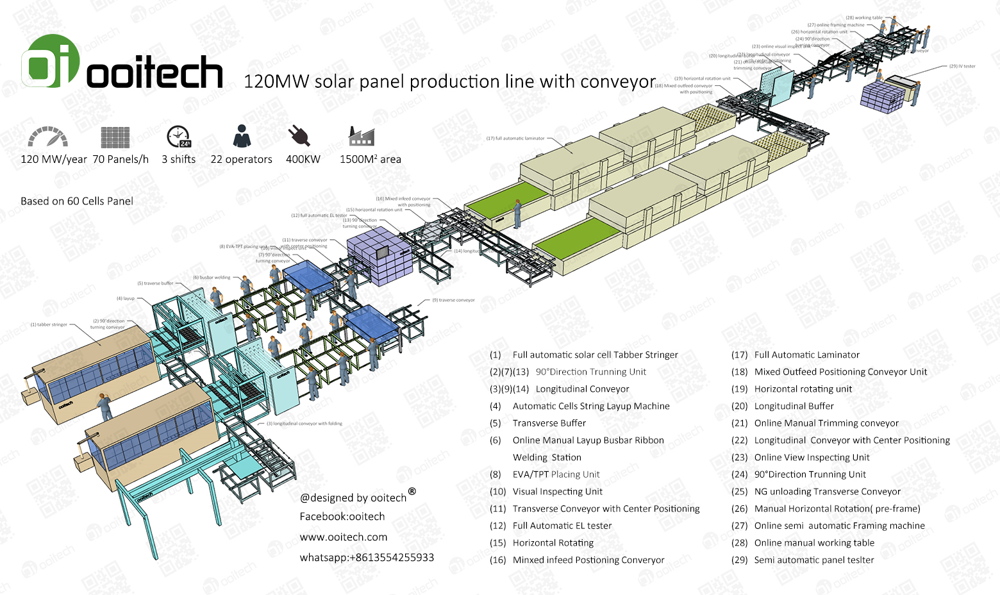

Ooitech, One-stop Solution For Solar Module Manufacturing Equipment.

Has The Following Required Machinery And Accessories

Ooitech “Turnkey Solution” Includes: Factory Construction, Facility Layout, Raw Materials BOM guidance, Production Procedure assitance, Solar Power Station installation technical support Etc.

Supply 10MW-250MW Solar Module Manufacturing Equipment

Update the traditional PV line to newest MBB solar panel production line.

Solar Cell Tabber Stringer Machine

Automatic Solder Bussing Machine

Solar Stringer Layup Machine - Solar Panel Production Line

Solar Stringer Layup Machine - Solar Panel Production Line High Speed Fiber Laser Cutting Machine For Solar Cell - 158 210 4000 PCS/H

High Speed Fiber Laser Cutting Machine For Solar Cell - 158 210 4000 PCS/H  Auto Soldering Bussing Machine

Auto Soldering Bussing Machine Solar Cell Non-Destructive Laser Scribing Machine 3600 PCS/H 6000PCS/H

Solar Cell Non-Destructive Laser Scribing Machine 3600 PCS/H 6000PCS/H 2022 Solar Cell Laser Scribing Machine With Auto Devide

2022 Solar Cell Laser Scribing Machine With Auto Devide 156-210 Mbb 50-60s/Panel Auto Solar Cell String Bussing Machine

156-210 Mbb 50-60s/Panel Auto Solar Cell String Bussing MachineBuilding 1, Zixin Industrial Park, Yangguang Ave,Jiangxia Economic Development Zone, Wuhan of China

Mon-Fri: 8.30AM-5.30PM (UTC+8)