Type:

Specification:

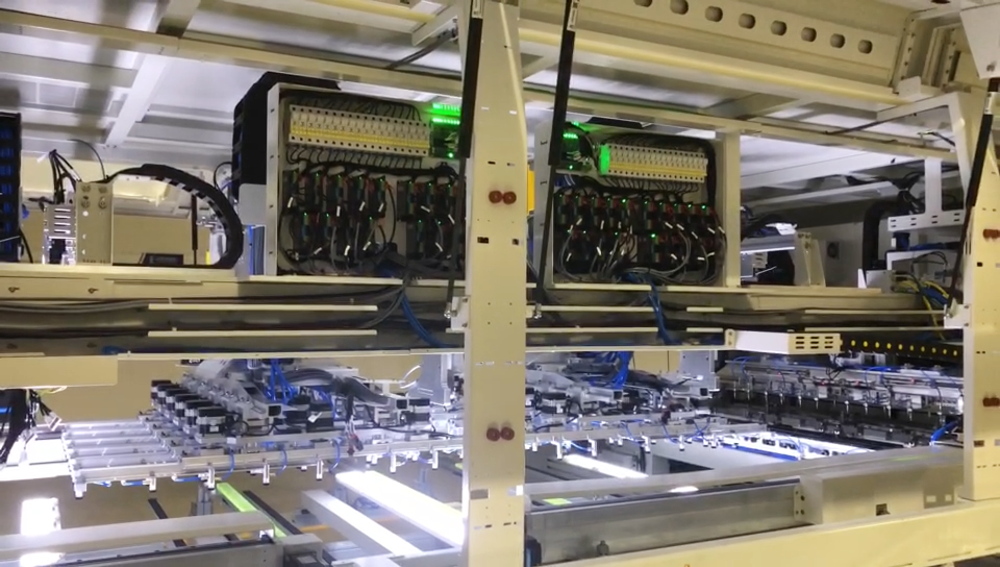

Auto Soldering Bussing Machine

Adopt the method of separating the cell string from the glass, and grab the cell string in the air, then to interconnected solder the head, middle and tail bus bar of the middle wire edition module at a certain height; It has the function of a roll feeding bus bar, bending U and L leads upwards.

|

MODEL |

ODH180-S |

|

Cell specification |

166/9BB main busbar distance 16.79mm(other cell is optional, which can be upgraded upon payment.) |

|

Module specification |

6 strings*10pcs half cell*2 6 strings*12pcs half cell*2 cell distance-0.5--4mm, string distance 1-6mm. |

|

Glass specification |

width 980-1400 *length 1630-2500 |

|

Cycle |

20S(exchange cycle of the transmission glass is 4.5s/module, thickness of the bus bar 0.35mm) |

|

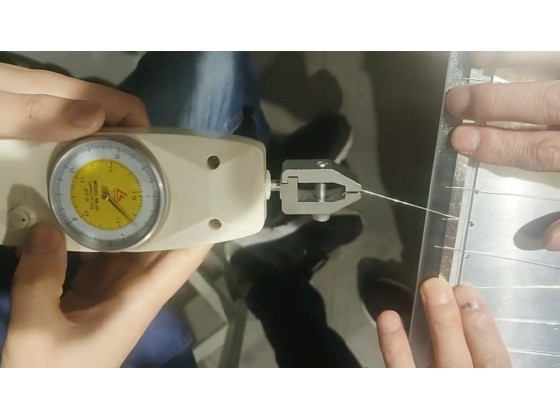

Soldering method |

electromagnetic |

|

Fragment rate |

0.2 (as per pcs) |

|

Pressure |

0.6—0.8MPa |

|

Flow rate |

2 m³/min |

|

Main pipe specifications |

outer diameter φ16 (2 pieces) |

|

Voltage |

Three-phase five-wire 380V/220V |

|

Frequency |

50-60Hz |

|

Power |

Peak 30KW, average 20KW |

|

Size |

4805×4620 (including two pipelines)×2260mm |

Ooitech, One-stop Solution For Solar Panel Production Line.

Has The Following Required Machinery And Accessories

Ooitech “Turnkey Solution” Includes: Factory Construction, Facility Layout, Raw Materials BOM guidance, Production Procedure assitance, Solar Power Station installation technical support Etc.

Supply 10MW-500MW Solar Panel Solar Panel Production Line

Update the traditional PV line to newest MBB solar panel production line.

Main machinery

Solar Cell Tabber Stringer Machine

Automatic Solder Bussing Machine

Solar Cell Laser Scribing Machine – Solar Panel Making Machine

Solar Cell Laser Scribing Machine – Solar Panel Making Machine Solar Cell Tester Solar Cell Sun Simulator - Solar Panel Making Machine

Solar Cell Tester Solar Cell Sun Simulator - Solar Panel Making Machine solar panel making process of Final test and Packing

solar panel making process of Final test and Packing High Speed Fiber Laser Cutting Machine For Solar Cell - 158 210 4000 PCS/H

High Speed Fiber Laser Cutting Machine For Solar Cell - 158 210 4000 PCS/H  Solar Stringer Layup Machine - Solar Panel Production Line

Solar Stringer Layup Machine - Solar Panel Production Line Tabber and Stringer Machine - MBB Solar Cell Stringer

Tabber and Stringer Machine - MBB Solar Cell StringerBuilding 1, Zixin Industrial Park, Yangguang Ave,Jiangxia Economic Development Zone, Wuhan of China

Mon-Fri: 8.30AM-5.30PM (UTC+8)