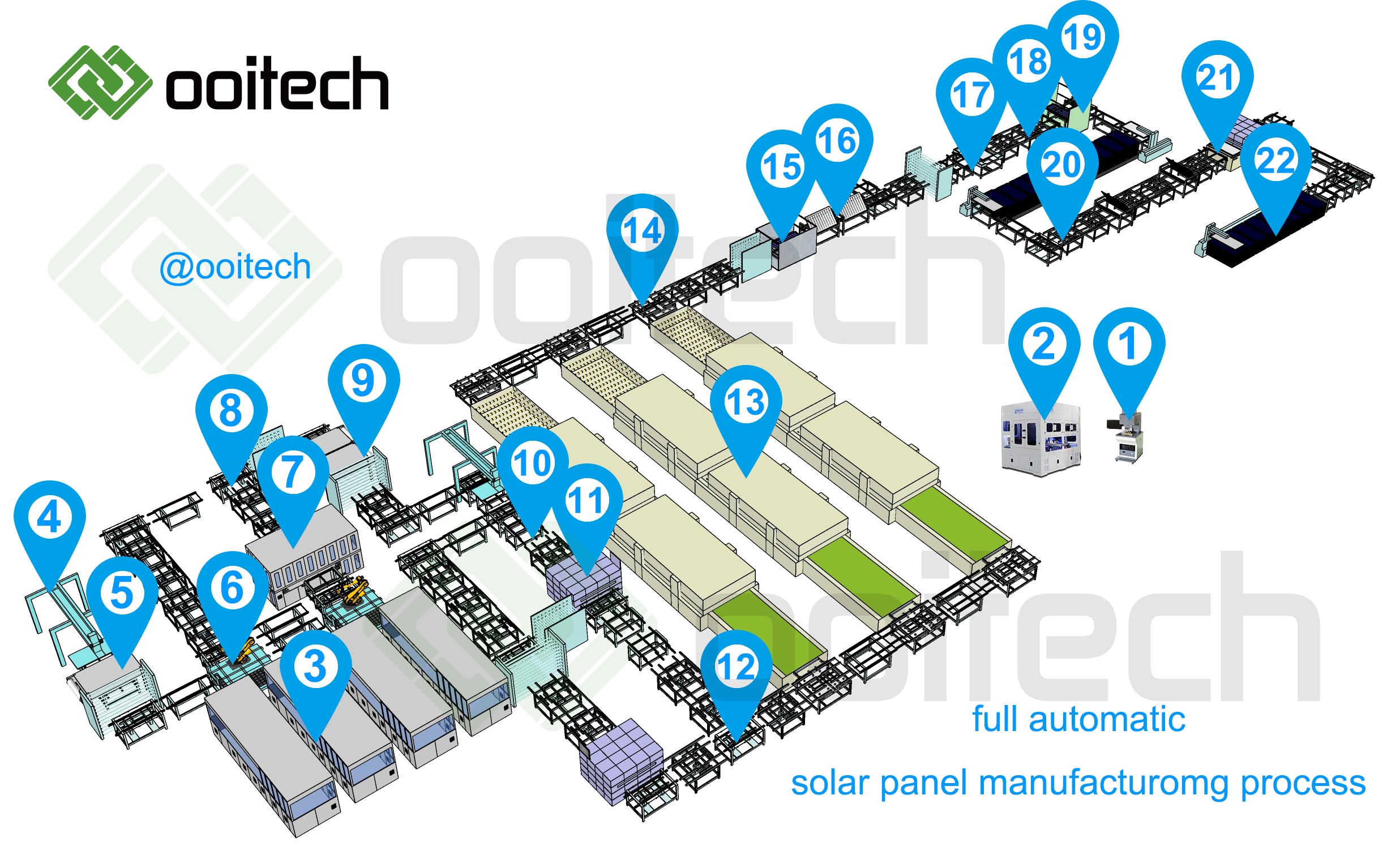

Processing Steps Raw materials & Tools

-

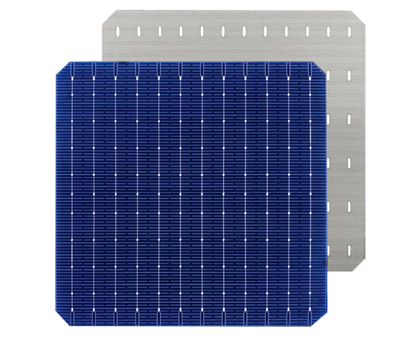

156-230 Solar Cells

-

Step 1

Solar Cell Testing

Test solar cells before welding

-

Solar Cells

-

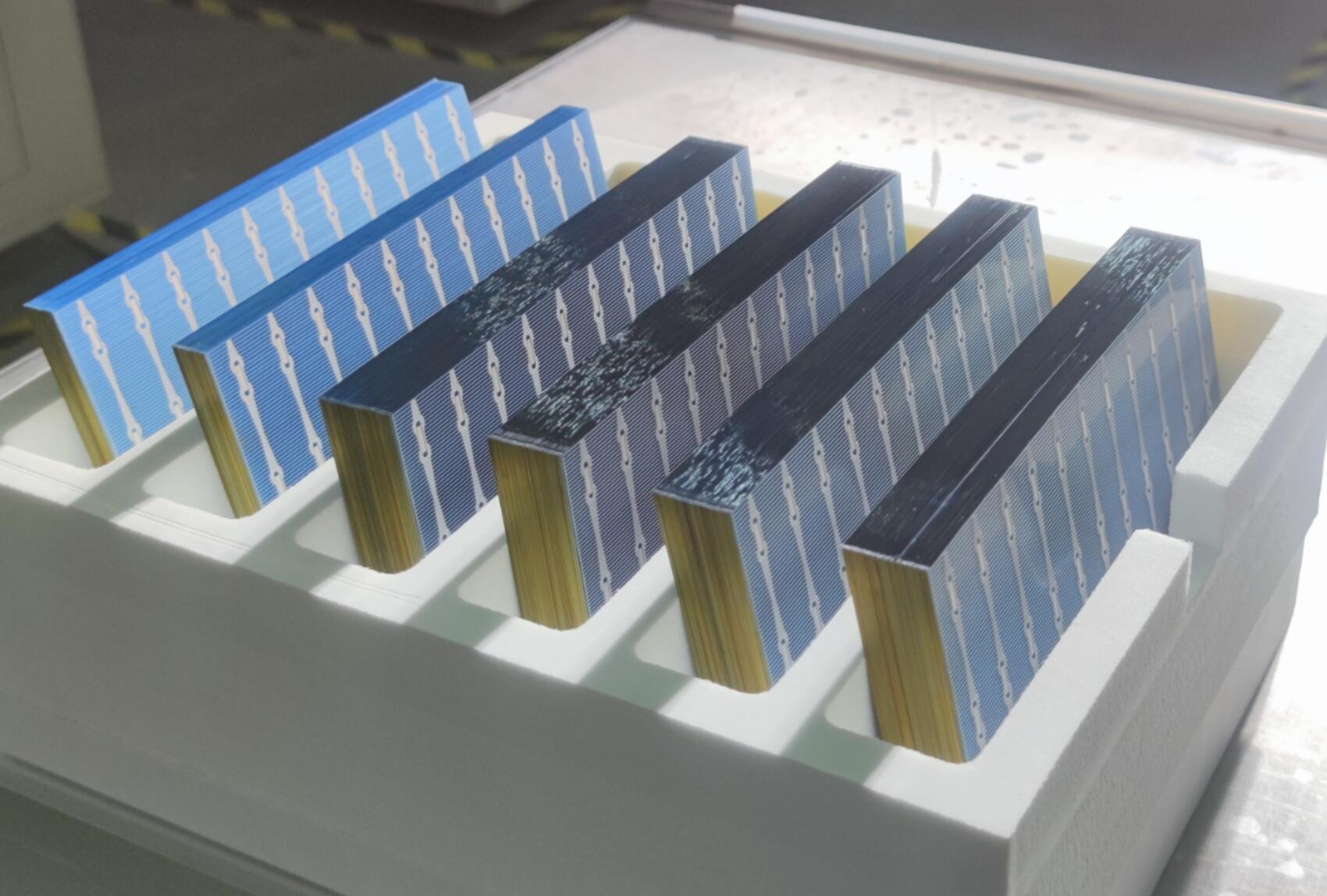

Step 2

Solar Cell Cutting

Cut solar cells to half 1/3 1/4 and more

-

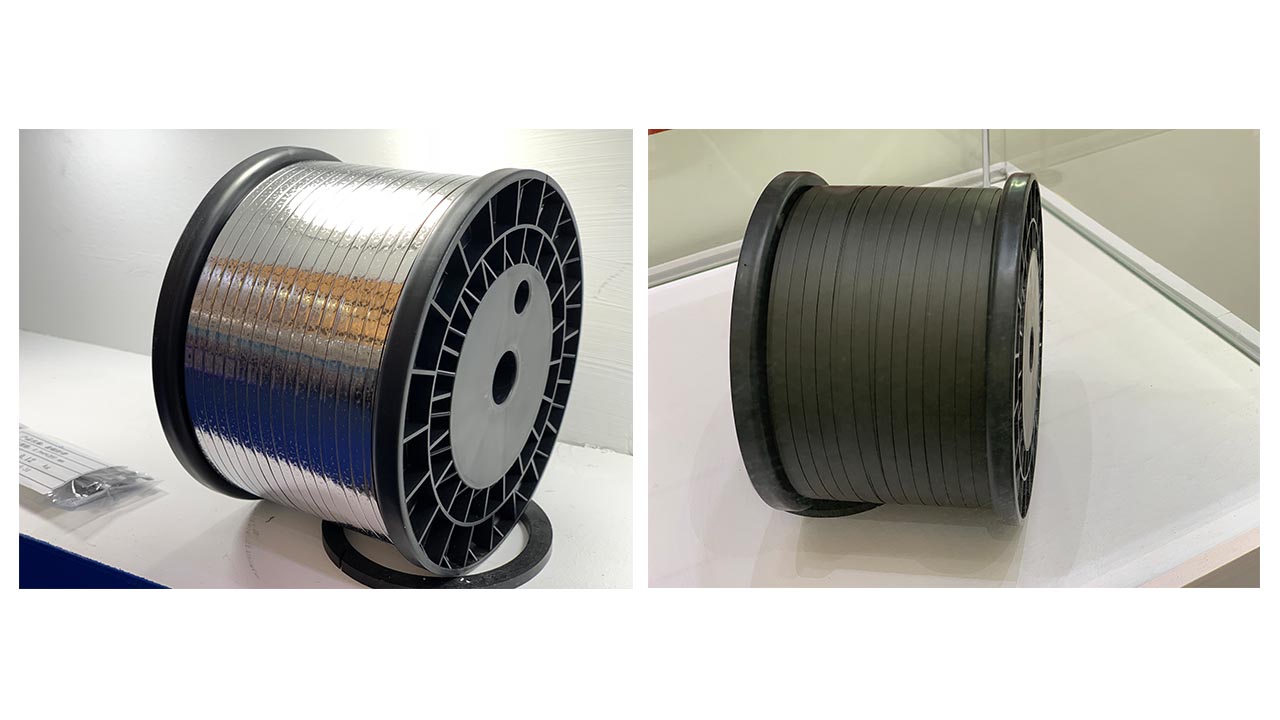

Solar Cells & Ribbons & Flux

-

Step 3

Solar Cell Welding & Tabbing

Tabbing solar cells to solar strings

-

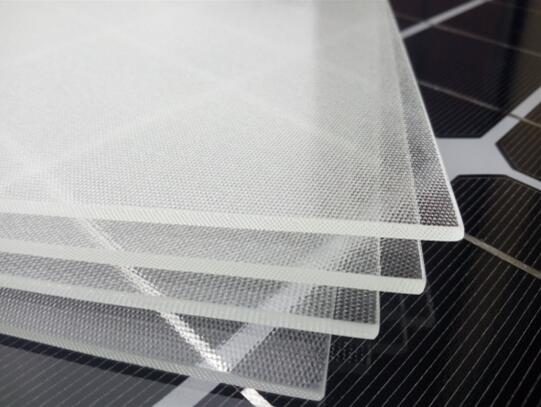

Solar Panel Glass

-

Step 4

Glass Loading

-

Solar EVA Film

-

Step 5

First EVA Layup

-

Solar Cell Strings

-

Step 6

Layup, Solar Cell Strings Layup

-

Busbar Ribbon & Flux

-

Step 7

Bussing

Interconnection Soldering

-

High Temperature Taps

-

Step 8

Taping

-

EVA and Backseet Films or Glass

-

Step 9

Second EVA and Backsheet or Glass

-

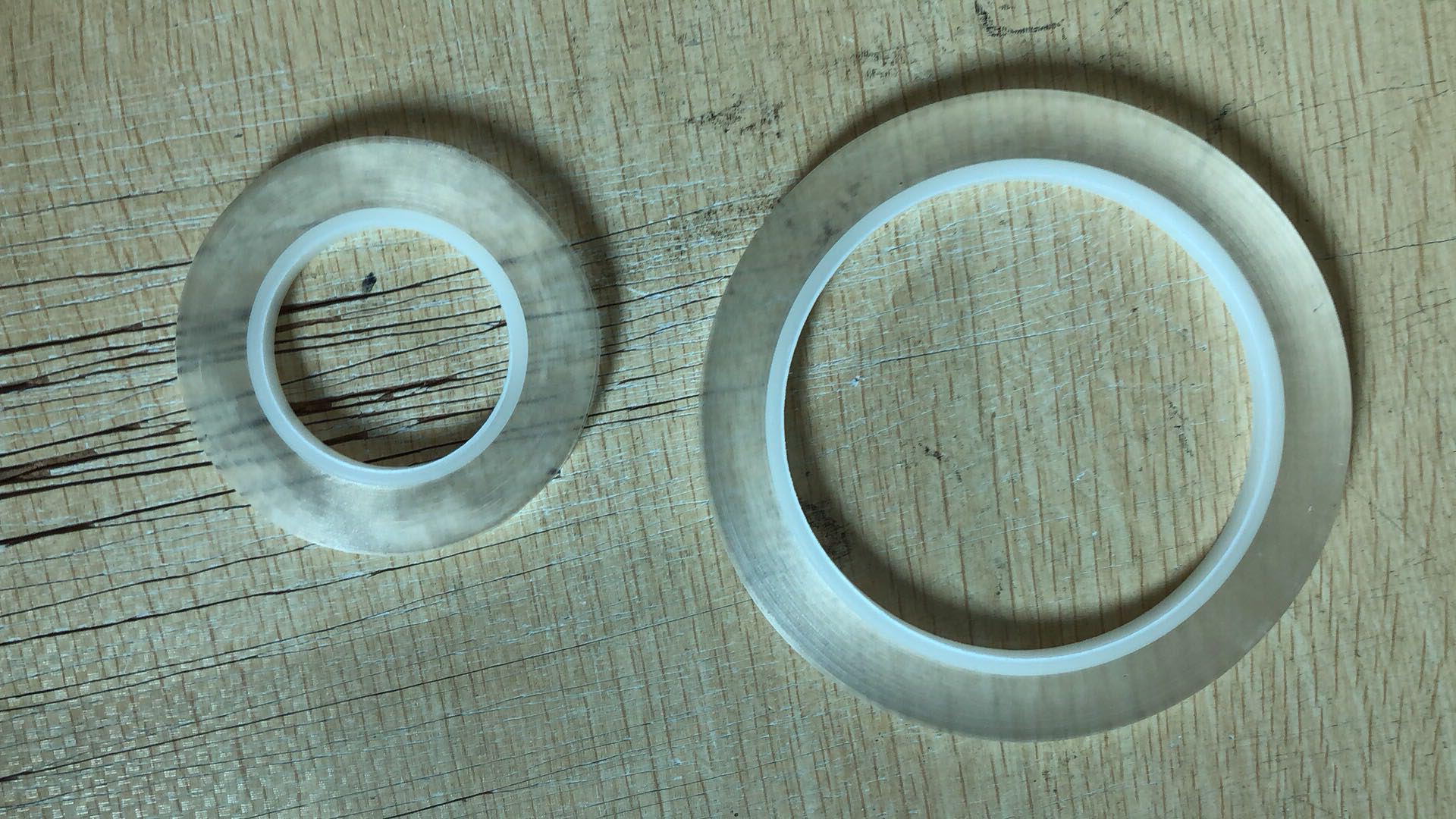

Insulation Sheet

-

Step 10

Insulation Sheet For Half Cut Panel

Isolated bus bar leads

-

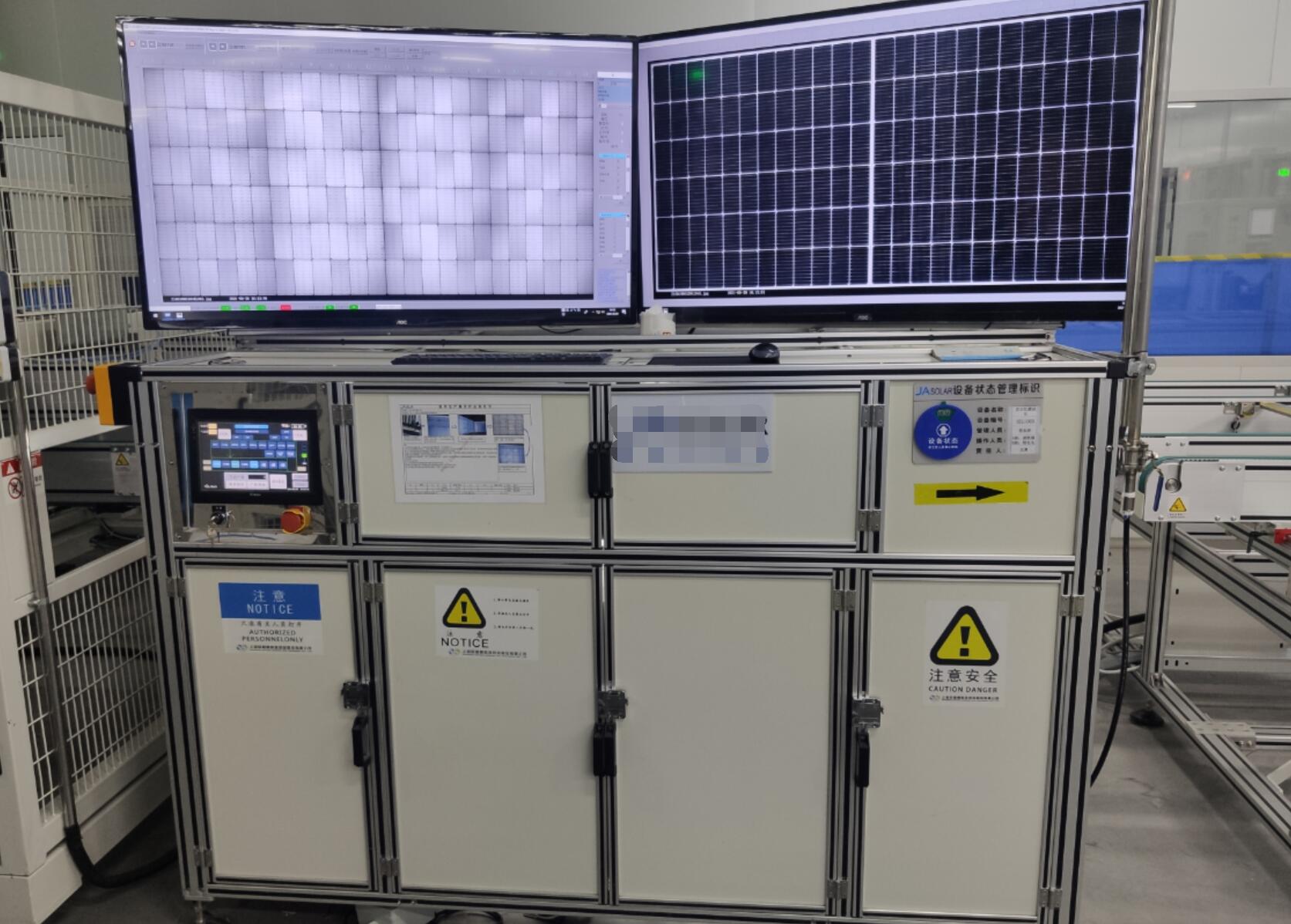

EL Tester

-

Step 11

Visual Inspect & EL Defect Test

-

Perforated Tape for Bifacial Solar Panels

-

Step 12

Taping for Bifacial Solar Panels

Taping for double glass panels

-

Solar Panel Laminator

-

Step 13

Solar Panel Laminating

Laminat multiple layers of materials together

-

Tearing Perforated Tape

-

Step 14

Tearing Perforated Tape For Double Glass Panels

-

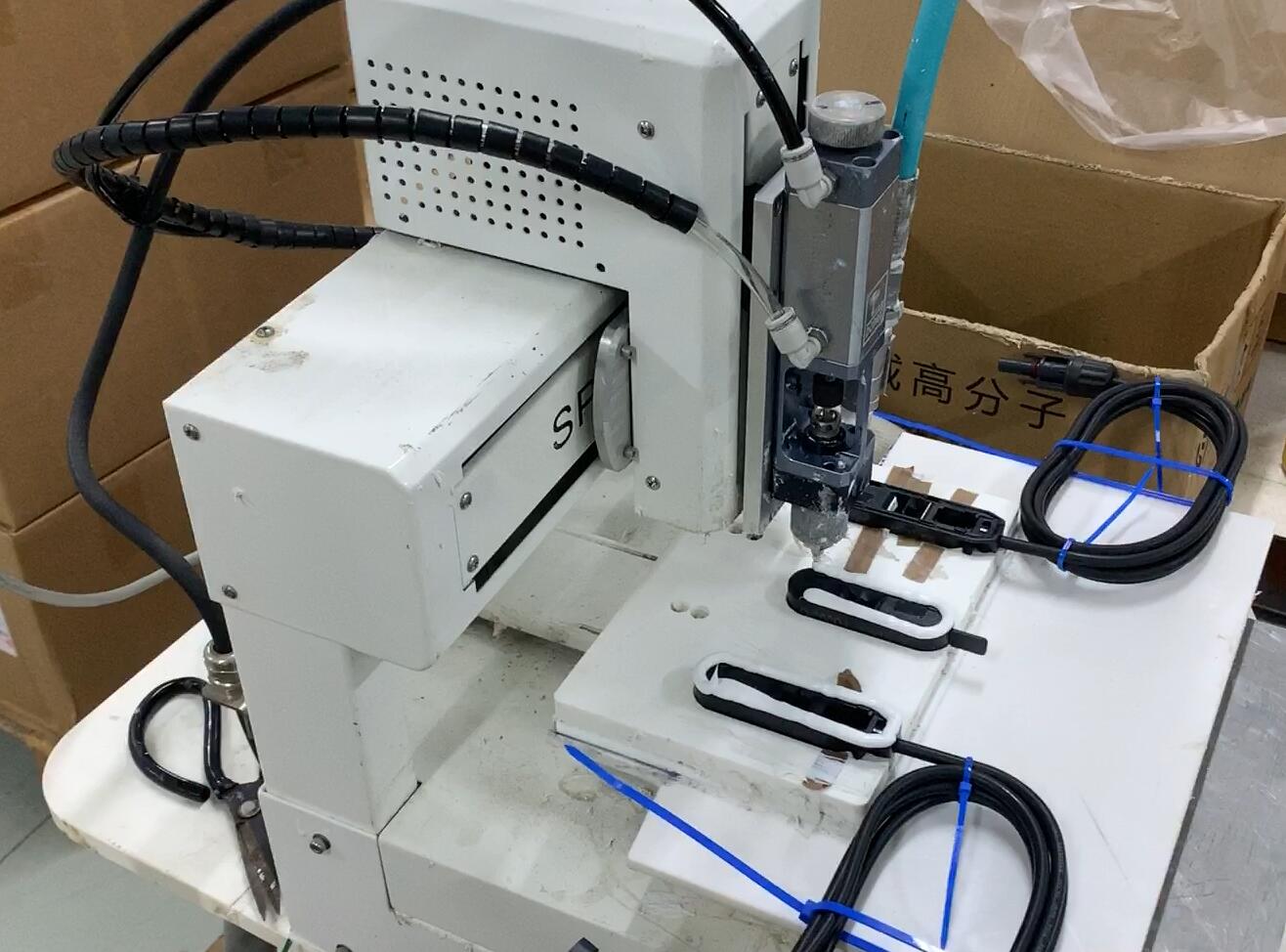

Trimming Tools or Machine

-

Step 15

Trimming

-

Flipping Inspection Station

-

Step 16

Flipping Inspection

-

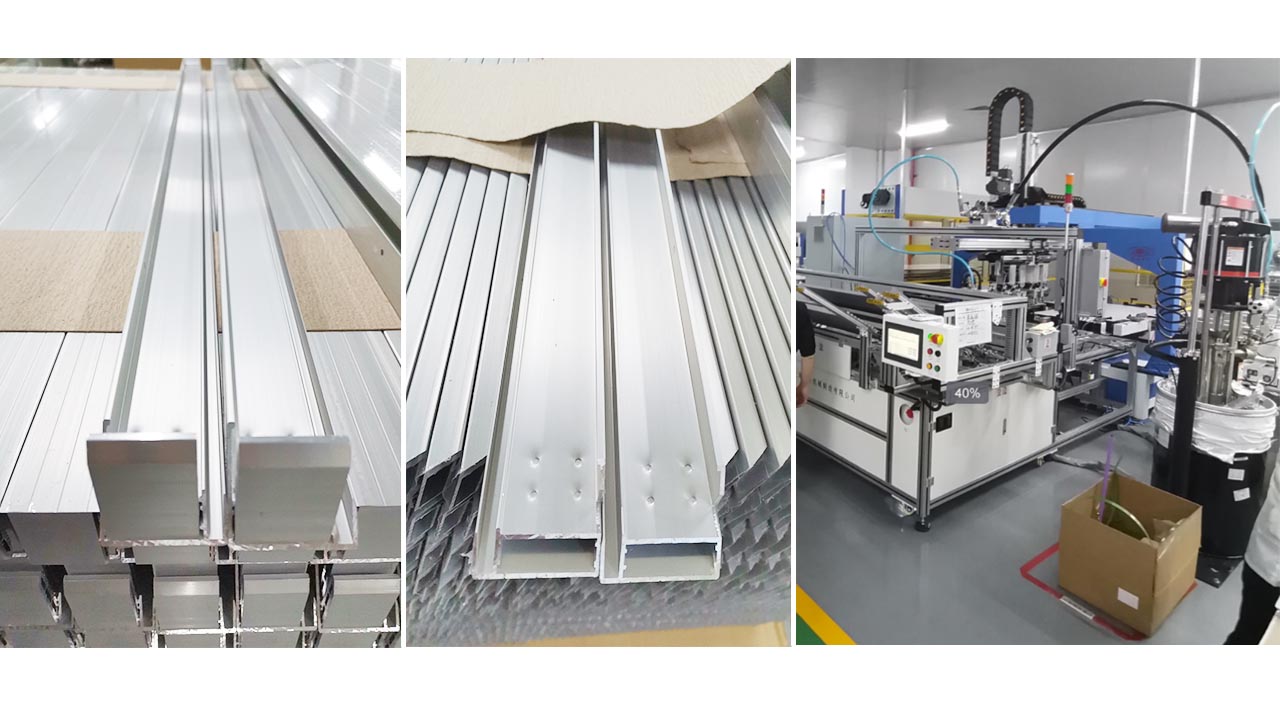

Aluminum Frame & Silicone Glue

-

Step 17

Gluing & Framing & Loading

-

Junction Box & Glue

-

Step 18

Junction Box Installation

-

AB Glue for Junction Box Potting

-

Step 19

Junction Box Potting

-

Clean Tools and Milling Tools

-

Step 20

Curing & Clean and Milling

-

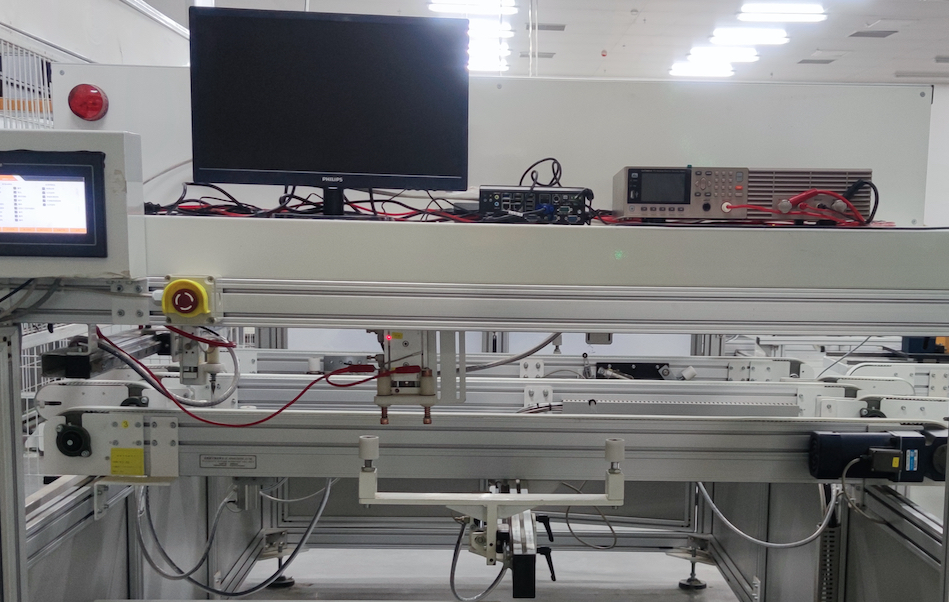

IV EL Tester & Insulation Hi-pot Tester

-

Step 21

IV EL Testing & Insulation Hi-pot Testing

-

Solar Panel Sorting & Package

-

Step 22

Solar Panel Sorting & Package