Type:

Specification:

|

Item |

OEL-S2400 |

|

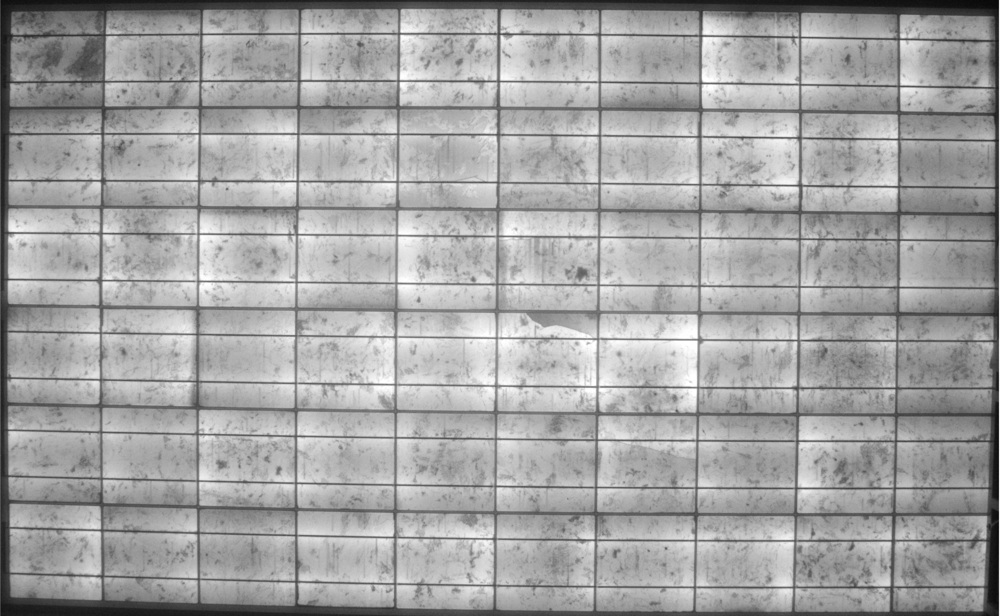

Capture Mode: |

Single Camera |

|

Run Mode: |

Offline |

|

Monitor Point: |

After Laminating |

|

Sample Stage: |

Super-white Tempered Glass |

|

Sample Size: |

≤2200mm*1100mm |

|

Operation Height: |

950mm |

|

Exposure Time: |

1 ~ 60s |

|

Current/Voltage: |

10A/60V |

|

Software: |

1.Interface for barcode scanning, naming files with barcode names; |

|

Detection Ability: |

crack, black spot, mixed wafers, process defect, cold solder joint. |

|

Configuration |

Testing host, computer, software |

Ooitech, One-stop Solution For Solar Panel Production.

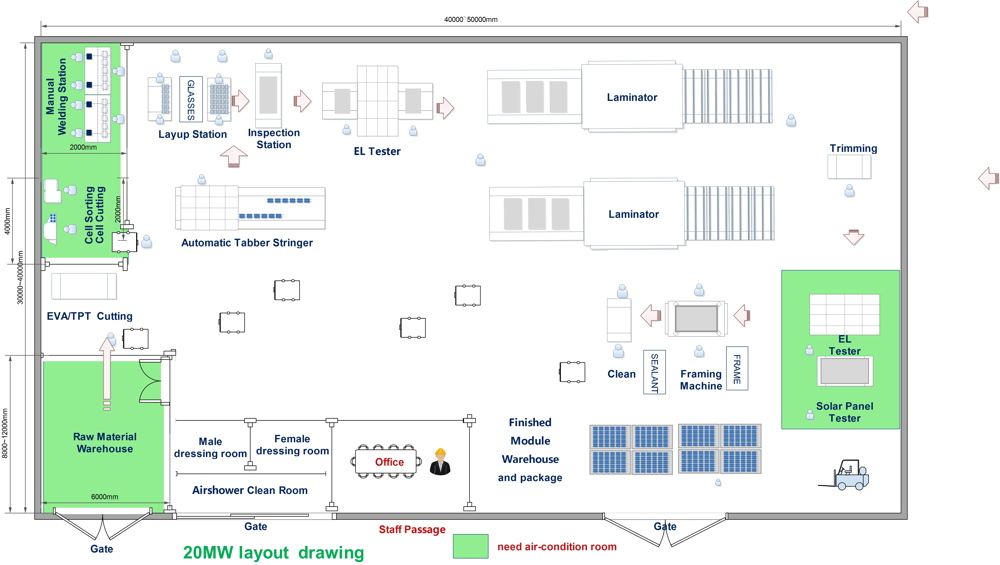

Has The Following Required Machinery And Accessories

Ooitech “Turnkey Solution” Includes: Factory Construction, Facility Layout, Raw Materials BOM guidance, Production Procedure assitance, Solar Power Station installation technical support Etc.

Supply 10MW-250MW Solar Module Manufacturing Equipment

Update the traditional PV line to newest MBB solar panel production line.

Solar Cell Tabber Stringer Machine

Automatic Solder Bussing Machine

Tabber Stringer - Full Automatic Solar Cell Tabber Stringer Solar Cell String Welding Machine

Tabber Stringer - Full Automatic Solar Cell Tabber Stringer Solar Cell String Welding Machine Full automatic solar panel laminator solar cell laminator

Full automatic solar panel laminator solar cell laminator  Visual Check and EL Inspection after lamiantion

Visual Check and EL Inspection after lamiantion Online manual solar panel Trimming

Online manual solar panel Trimming Online automatic solar panel framing machine and aluminum frame glue station

Online automatic solar panel framing machine and aluminum frame glue station  Online automatically Curing Room

Online automatically Curing RoomBuilding 1, Zixin Industrial Park, Yangguang Ave,Jiangxia Economic Development Zone, Wuhan of China

Mon-Fri: 8.30AM-5.30PM (UTC+8)